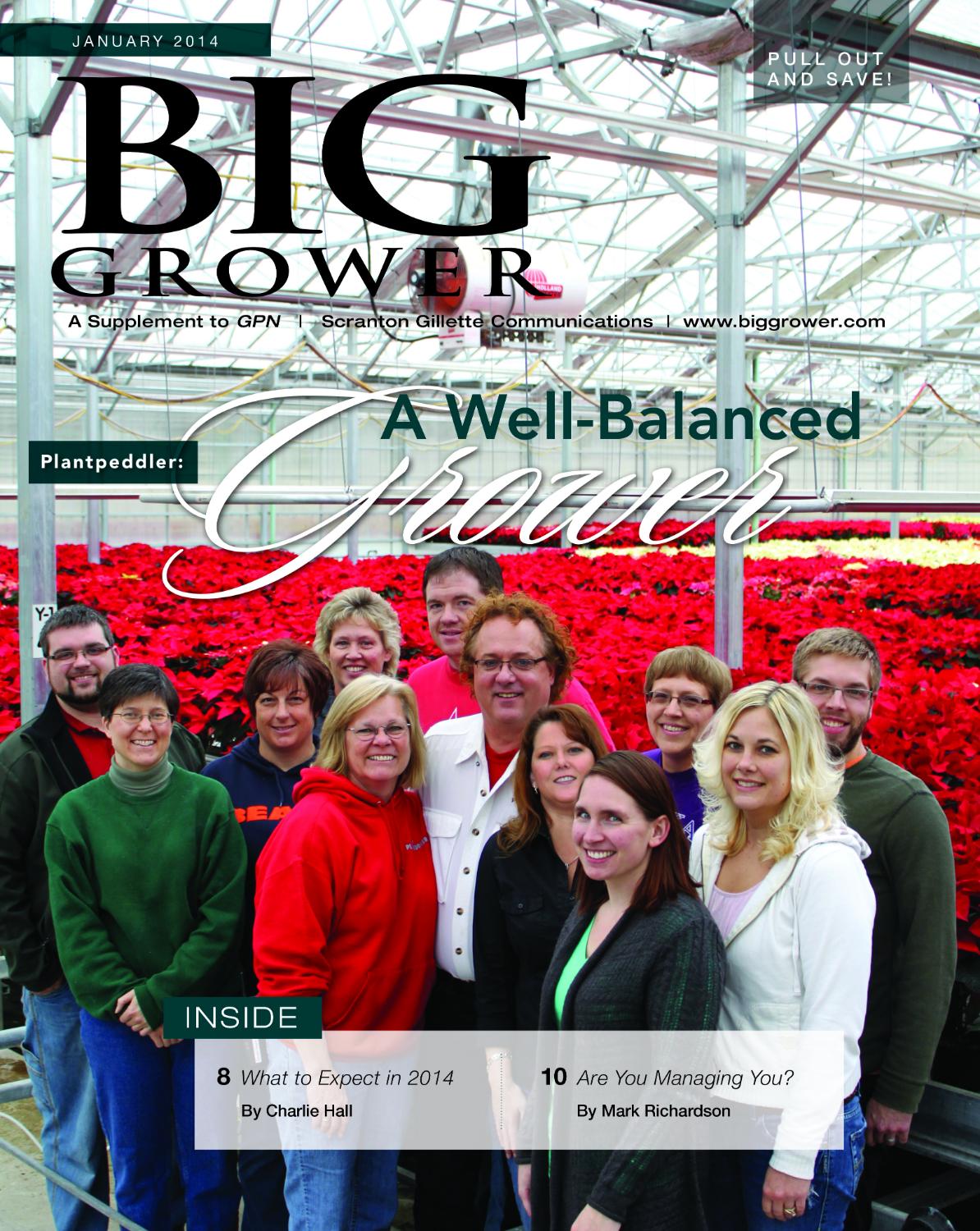

COVER STORY — A Well-Balanced Grower

One of the biggest challenges facing growers today is figuring out how to avoid the peaks and valleys of income and expenses over a 12-month period in a notoriously seasonal business. It can be tricky balancing a P&L statement when the bulk of a com- pany’s income comes at one time of the year — such as spring.

For the past 30+ years, Mike and Rachel Gooder at Plantpeddler in Cresco, Iowa, have been constantly working on perfecting their balancing act to grow their company and meet this challenge.

Through product diversity, hard work, creativity, passion and the willingness to take chances, Plantpeddler has evolved and expanded from a small retail operation in rural Iowa to a prominent Midwestern grower of finished plants, young plants, edibles and its original retail garden center.

Peddling All Kinds of Plants

For the Gooders, 1980 was a very busy year. They graduated from Iowa State University in May, got married in June and a week after that, purchased Cresco Greenhouses where Mike had worked when he was in high school.

Back then the “production greenhouses” grew product pretty much exclusively for the retail operation. In 1984, after a few years of retail only, Plantpeddler launched its wholesale business selling finished plants to regional customers.

The grower kept growing and in 2000 Plantpeddler Young Plants was born. Today that portion of the company offers nearly 1,000 different plant varieties in nearly 2,000 rooted cutting configurations to more than 2,500 producers nationwide.

The company’s customer base for finished plants has continued to expand to many different types of customers, and now Plantpeddler is one of the leading live goods suppliers to many of the major and regional grocery chains in the Midwest. Currently, finished plant sales make up approximately half of all of Plantpeddler’s revenue.

About five years ago, Plantpeddler launched Stone Creek Farms — a product line of fresh, locally grown produce — to create a new revenue stream and “to balance the seasonality of the ornamental product lines and divisions.”

By expanding into these other types of businesses with different products and production schedules, Mike says, the company has been able to “cure our calendar,” eliminate “dead months” in the greenhouse and provide year- round income for the company.

“It really takes 52 weeks of cash flow [to run a company], even if you may not have income all 52 weeks,” he says.

So with a fiscal year that starts on Oct. 1, Mike and Rachel feel Plantpeddler’s diversified offerings provide a better-balanced cash flow that eases the burden on all four fiscal quarters. First quarter is poinsettia and fall vegetable sales; second quarter is young plant sales; third quarter is the biggest quarter of the year — spring; and fourth quarter is a blend of poinsettias, fall mums and young plants.

“Our customers, our crop mix, the seasons and weather we are dealing with, how we use our facilities, it’s all a constant evolution,” Mike states. “We’ve always felt it was the perfect mix of agriculture and manufacturing.”

“And since we started the company no two days have ever been the same!” Rachel says.

Midwestern Mentality

Located in Cresco, Iowa, or as Mike likes to call it “perfectly in the middle of nowhere,” Plantpeddler is actually situated nicely to service customers in seven Midwestern states with finished plants and in all 50 states and Canada with young plant products.

“Our focus is close to home but there are approximately 40 million people within about a 200-mile radius of our location,” Mike says, and Plantpeddler has access to most of the major Midwestern cities like Chicago, Minneapolis/St. Paul, St. Louis, Madison, Milwaukee, Des Moines and Kansas City.

A lot of the company’s finished business is with grocery stores, hardware stores, independent garden centers and drug stores in the Midwest.

“The reason those market segments do well for us is that there is a local ownership aspect to those stores — especially hardware stores,” Mike says. “The reason consumers come into those types of stores is because the manager is local, the employees are local. It is a neighborhood store,” Mike remarks. “There is a relationship with the customers — a trust bond.”

That is the same kind of relationship Plantpeddler likes to have with its customers. “We add value to our products at every step of the process,” from the URC to the finished plant at retail. “We bring value to our products and our customers bring that value to the consumer.”

Mike says that since the company started as a small town retail business they have always maintained that mindset — even though the company continued to grow into a much larger and more complex business. “We want to be that one-stop shop, year-round for our customers,” Mike states.

Quick response to the different types of customers’ needs also is paramount. It doesn’t matter if it is a finished plant or a young plant order, the goal is always to accurately fulfill that customer’s request as fast as possible.

“One of the things that we know we are strong at is our ability to be an ‘at-once’ company. So we are constantly building on that ability to fulfill [orders quickly],” Mike says.

Breeding Success for Everyone

Over the years and because of the diversity of Plantpeddler’s products, the company has established strategic relationships with many of the different breeding companies. “We have really positioned ourselves well in the genetics that we grow,” especially in the begonia and geranium and most recently, the poinsettia categories, Mike states.

Plantpeddler is currently working with approximately 25 primary breeding companies along with some specialty breeders — and all five of the major poinsettia breeders. “We love to bring innovative products to our young plant customers and retailers,” Mike says.

Plantpeddler’s trial gardens are a showcase for the breeders’ products and for the company’s production capabilities. “We provide value to the breeding companies,” and that provides the company with access to exclusive information and products, Mike says. “We have learned tremendously from our trial gardens and hopefully we can give our breeders some guidance from what we have learned.”

Every August, Plantpeddler presents its Variety Day for customers and others in the industry to highlight the different genetics from the breeders. In 2013, nearly 1,000 varieties were on display in the Plantpeddler trial gardens.

When it comes to the trial gardens and working with the breeders, “it is all about continually working on a better product,” Mike says. “It is one more insurance policy that our growers will have 100 percent performing varieties and that consumers will be successful.”

And that is a win-win-win situation for everyone.

Talk About the Passion

Like many other growers, the Gooders are passionate about their business and the future of the industry.

For Mike the path to a career in horticulture began when he was very young. “I got started with a milk carton, some Iowa black dirt and some marigold seeds in Mrs. Leslie’s kindergarten class. That was my official start in horticulture.”

“I have always felt that we as an industry should support a national program for getting youth into horticulture,” he states.

He believes growers need to “reach out to any school we can find” and donate excess plant materials, containers and media to help get kids involved in gardening as early as possible. “Then maybe on a one-by-one company basis, we can turn the tide” and start growing future gardeners.

He also is a big proponent of the industry developing a marketing initiative to help increase consumption of green goods.

“Over the years we have had a couple of different chances to create [an industry-wide marketing program]” like the dairy and beef industry campaigns, but it hasn’t happened. That is one of my burn points,” Mike declares.

“We have outstanding products that we dedicate our lives to. We have breeders who risk millions of dollars to create products of beauty. The only way we are going to create demand [for our products] is to be in the face of the consumer.

“We need to let consumers know more and be more aware of our products. We need to fight for that! It is time where we need to be proactive as an industry,” Mike declares.

“It is going to take creativity [from everyone]. But it’s time we all work together!”

Plantpeddler at a Glance:

Location: Cresco, Iowa

Key personnel: Mike Gooder, president and chief executive officer; Rachel Gooder, vice president and chief operating officer; Joan Leuenberger, CPA, chief financial officer; Stacy Bryant, office manager/key account sales; Julian Kroll, hard goods purchasing/IT; Edie Slifka, young plant customer support/logistics; Brenda Kubik, young plant production manager; Jason Sbiral, facility manager/IPM manager; Connie Goodman, wholesale production manager; Amanda Ludwig, live goods purchasing; and Aaron TerBeest and Kimberly Kleppe, sales and customer support.

Number of Employees: 30 to 40 year-round; 90 to 100 during their peak sticking season.

Customers: Finished plant customers include grocery stores, hard- ware stores, independent garden centers and drug stores throughout the Midwest. Young plant business serves growers of all sizes across the United States and Canada.

Website: www.plantpeddler.com

Eastern Europe Comes to Northern Iowa

For the past three years, Plantpeddler has been participating in an international internship pro- gram called Communicating for Agriculture Education Programs (CAEP) that has brought Ukrainian students to Cresco, Iowa, to learn about horticulture.

According to the CAEP website, the program allows college students from other countries “to experience the world through agricultural exchange, and provide an opportunity for rural families to be touched by other cultures, cultivating lifelong friendships.”

Rachel Gooder found out about CAEP from the owner of an Iowa orchard who had been participating in the program. She says the students receive real-world, practical, hands-on experience that they will not find in their own countries.

“The program has been phenomenal,” Rachel says. “The [interns] are a really good crew of workers who all really want to learn about horticulture.”

Once they are accepted by CAEP, the students receive a one-year J-1 training visa and are matched up with U.S. companies. CAEP helps take care of all of the intern’s immigration logistics to get them into America.

According to Joan Leuenberger, Plantpeddler’s chief financial officer, who oversees the intern program, “It is a stringent process for the students to get into the program.

We are trying to transfer horticulture industry knowledge but also expose them to American culture.”

“We have been growing the program every year for the past three years because it has been very successful for us.” Currently 10 students from the Ukraine are employed at Plantpeddler.

Once they are in Cresco, the students are exposed to the many different aspects of Plantpeddler and the United States. In addition to the in-depth horticulture education, Plantpeddler must provide the interns with housing and basic transportation during their stay.

“It is really fun because [the interns] really integrate into our community. When you live in a town of 4,000 people, it kind of changes the fabric of our little rural town, ” Mike Gooder adds.

For more information on this program, go to www.caep.org.

A Berry Interesting Product

Plantpeddler’s Stone Creek Farm produce line was introduced about five years ago. It was developed to help balance the company’s production calendar and income. “We were kind of on the front edge of the [edibles] wave and we have grown everything from arugula to zucchini,” Mike says.

Mike and Rachel did a lot of work before launching the Stone Creek Farms concept. It was created to complement ornamental sales, not supplant them. “Our mission statement when we started Stone Creek Farms, based on our overall philosophy and based on our numbers, has always been ornamentals first,” Mike says.

But one of the SCF products the Gooders have high hopes for is the aronia berry. In their spare time, they like to make homemade wine and while looking for the right berries for their hobby they learned about aronia berries and “that they make killer red wine.”

Rachel says the aronia berry is native to the Midwest and was used hundreds of years ago by Native Americans. The dark purple berry is high in antioxidants, easy to grow, doesn’t have any pest issues and is deer-resistant.

“The bushes are easy to grow. You can grow them anywhere,” Rachel says. “And they will produce berries for 25 years.”

The Gooders originally propagated aronia berry bushes on their farm and now offer plugs through the company’s young plant program. But they are also working with another partner to take the product to the next level of commercialization

Video Library

Video Library